Quote:

Originally Posted by BRUTAL64

You have the right idea. ANY sharp edge can be smoothed/rounded to keep cracks from starting.

Don't worry about the highlighted area---the crank will break at #1 journal long before anything else will break.

What is the casting number of the crank you are using??

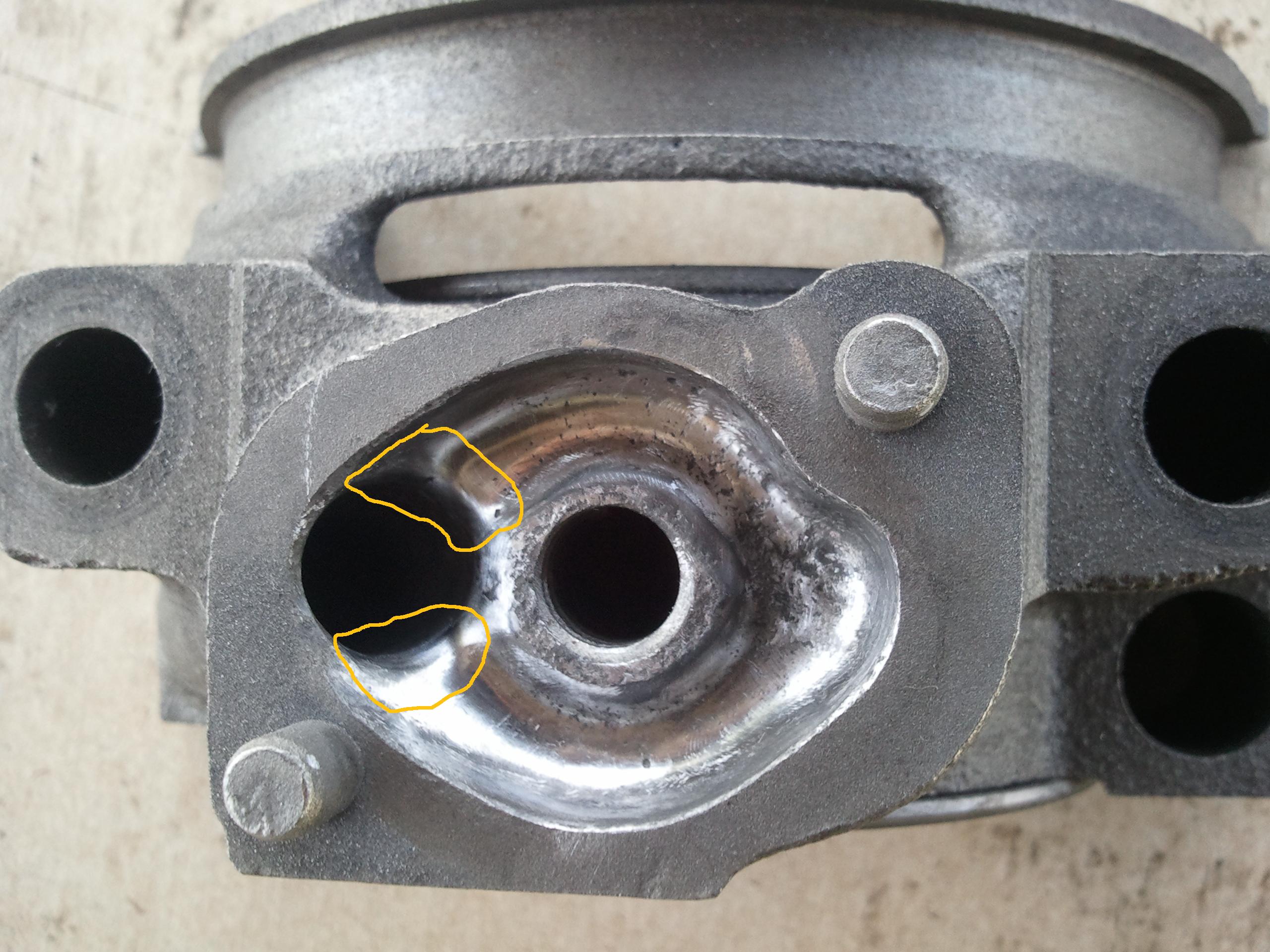

The oil feed oil on the rear main cap still needes some work. Try to make the entrance into the hole more rounded --- like two troughs going into the hole.

Noticed you are using a CAST crank. What kind of power/rpm are going to be putting out.

A GOOD cast crank can handle SOME power but rpm can be a bigger problem.

Are you going to deburr/ stress releive the block?

What is the casting number and year of your block?

In the timing chain area what 010 or 020 numbers (how many) are there cast into the block?

It's a four bolt- give me the the numbers cast onto the top of the three center main caps.

Can you give me a picture of the lifter valley from lifters (lifters hole bosses also) to top edge of block?

Also a picture of the front and rear cam hole castings.

All these questions do have a GOOD reason.

|

I'll get you some pictures later along with pictures of the casting numbers. I did deburr the block. I'm estimating peak horsepower to be somewhere between 6500-6800 so the cast crank should be fine. We plan to gear the car so that we hit the rpm where peak horsepower occurs just past the halfway mark on the straights.

I assume what you are saying on the oil main is to smooth out the area that I circled so that it is not as sharp of a turn entering the hole?