|

Quote:

|

Quote:

|

Quote:

Is the other carrier "centered?" |

Quote:

|

Quote:

|

So obviously the Exploder is offset for a transfer case, so the Mustang looks like a good fit. If that means gear change, rather than trying to find a LSD, we can get a spool for $90, a gear set for $150., and set it up killer. Maybe I should take Ben down to Unitrax, and see what they might have laying around. Time to start whooing some venders. They might also provide some good advice/guidence concerning this adventure.

As for brakes, as long as the car stops by the last turn off, they are fine.:sm_laughing: |

Quote:

I have a set of 3.55 gears for an 8.8 that only have 7000 miles on them. Switched them for 4.10s. That may work better for that 4 speed anyway with a 25" - 26" tire. |

The Explorer center section looks centered. I'll measure mine today and tell you for certain. Also, most Explorers came with 3.73 gears which will be a good gear for the RX-Snake.

|

Quote:

3.55 = 127mph 3.73 = 121mph I think we'll have the power to weight to ring out the taller gear and have a faster trap/et. |

Quote:

|

Quote:

Also know that a Slick will grow as you go sown the track. So if we use a 26 inch slick it will act like a taller tire further down. |

Quote:

|

Quote:

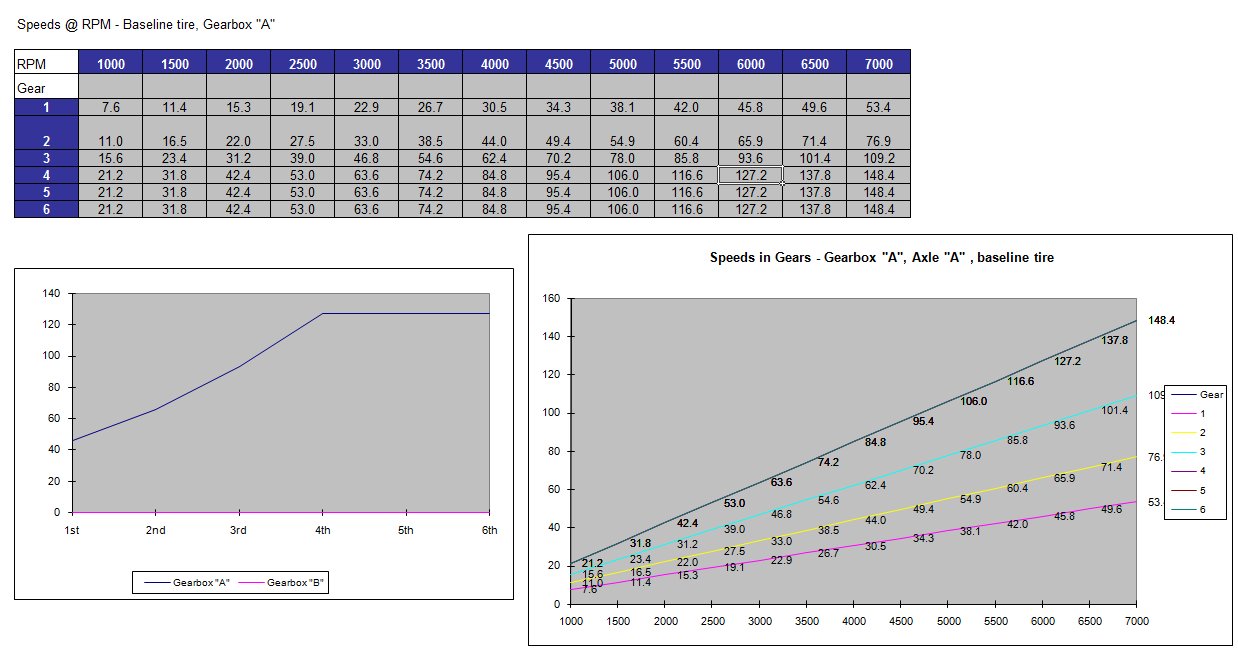

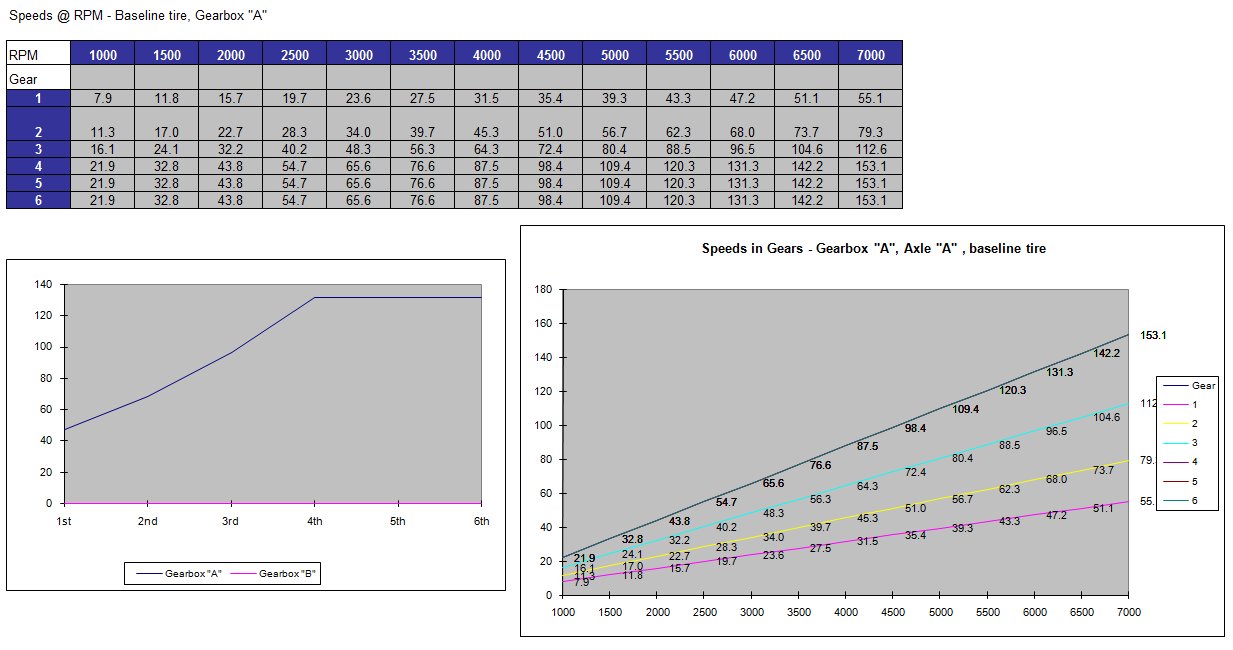

Here's a nice accurate graph of a wide ratio top loader, 3.55 gears and 275/50x15 tires. The engine turns the trans turns the axle (not a lop of slop there) turns the tires. Pressure and rotational inertia can have some effect on "real" diameter and effect total final "gearing", but the margin of error would be a couple mph at most I would think.  |

Quote:

|

If weight is irrelevent, let's make the RX 20,000lbs. Should be good for traction.:smack:

|

Quote:

|

Quote:

|

Quote:

If I remember correctly it was around 6200 to 6500 rpm. I'm just saying a 3.55 gear MIGHT be too tall in the real world. I remember when I was running the 1/4 I was just shifting into forth just before I hit the light with the 3.55s. Not saying you are wrong , just stating a little real world testing would help here.:drink: |

Quote:

|

Quote:

|

Quote:

Without allowing for any growth and/or variances in the tire, a 28" tire with 3.73 gears will be running ~134 MPH @ 6000 RPM in fourth gear. |

Quote:

What ever could be MORE important than Motorgen??????????:rant: Hey, I just noticed I have OVER 1000 posts on this site. Damn, what the hell would I have to say that takes that many posts???????:huh::o:suicide: |

Quote:

My implicit assumption was that given our power to weight ratio, the engine would have sufficient power to rapidly reach redline given either a 3.55 or 3.73 axle. I was isolating a single variable in the system. There is basically no cost difference with either axle, but there plausibly could be a few mph and/or couple tenths penalty one way or the other. My hypothesis would be that with the power to weight we're likely to have, the "slightly" taller rear axle, would result in faster ET and Trap in the 1/4. However, it is possible that while the top potential speed is lower with the shorter gear, it may reach that top speed faster enough to result in a faster ET. :huh: To model this properly we'd be changing from simple arithmetic to real math. I'm looking for accumulated experience. Anyway, this is getting to the kinda splitting hair territory, but I enjoy that, so you have to endure it. :pot_stir: :smack: |

Quote:

|

Quote:

6,000rpm (shift/redline) Wide Ratio Top Loader 3.73 Axle 275/60x15 Tire If we have enough power to turn this gearing (my guess is around 500 BHP with this much weight, very rough) and make it stick for a wicked 60', and click off clean shifts, this would be a consistent low mid 10 second pass.  |

Quote:

You mean endure it....:rolling::rolling::rolling::rolling:like a tooth ache???? |

Quote:

MPH= ((RPM/(rear gear ratio*trans gear ratio))*60)/tire revs per mile RPM = 6000 Rear Gear = 3.73 Trans gear ratio = 1 Tire revs per mile = 720.49 MPH = 133.95708 Thus my earlier posting that it would be ~134 MPH. |

Quote:

|

Quote:

|

Quote:

So how many tire revs per mile does your sheet calculate? Because I calculated the revs per mile using the exact circumference of what a 275-60-15 tire should be. I don't allow for any variances and frankly I don't know how your spreadsheet could do that accurately, considering different variances between tire, tranny, and rear-end manufacturers. Here is my calculation. (((275/25.4)*.6)*2)+15 = 27.992125 (Tire diameter) 27.992125 * 3.1416 = 87.940059 (Tire circumference in inches) 87.940059/12 = 7.3283382 (Tire circumference in feet) 5280/7.3283382 = 720.49076 (tire revolutions per mile) |

BTW. I'll be going to Pomona. Anything you want me to be on the lookout for?

|

Quote:

- Repair Parts for the 174 - Holley 750 CFM Carb with four corner idle set (if on the pretty cheap side relative to new, might give that a whirl first) - Radiator for an 2nd Gen RX-7, we don't have one - Alternator w/Bracket - Starter These I can get new from Summit, but if you see them cheap: - Scatter Shield for Top Loader - Long Tube Swap Headers for SBF I trust your judgement, send me the bill. :sm_up_there: |

Quote:

=(63360/(((B9/25.4*(D9/100)*2)+F9)*3.141597)) *0.99 B9 = Section Width D9 = Aspect Ratio F9 = Rim Diamter It's basically the same as yours, EXCEPT for the last multiplication. This actually reduces the number of revs per mile and therefore increase the speed for a given RPM. I believe it was the original desginers intention to account for growth in the tire as a function of heat/pressure and rotational inertia.:huh: However, my sheet also inlucdes a big reduction when calculating the speed for a given tire/axle/gear @ RPM x. =((D18/(B21*B28*H9))*60)*0.97 D18= RPM (shift or redline, or whatever you want to put in, I'm assuming 6k) B21=Gear ratio B28=Axle ratio H9=tire revs per mile The final multiplication is an additional reduction I forgot about. If I had to guess it's for nonlockup auto trans, but that's just a guess. Thanks for the catch. :thumbs_up: I'll take out these constants for future calculations so we're comparing apples to apples. |

Quote:

Radiator, I would hold off on. I may get that REAL cheap from a friend. (He owns Anaheim Radiator). He can probably make us one custom. |

Quote:

|

Quote:

|

Quote:

|

Quote:

|

Quote:

|

Quote:

|

| All times are GMT -7. The time now is 09:55 AM. |

Powered by vBulletin® Version 3.6.8

Copyright ©2000 - 2024, Jelsoft Enterprises Ltd.